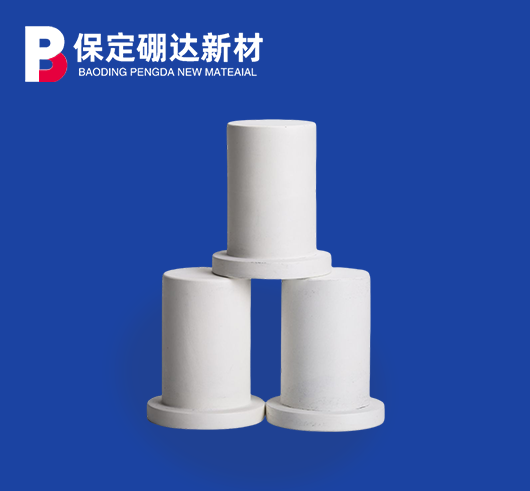

At present, there are many kinds of boron nitride products in the domestic market, although the manufacturing process is much the same, but the main difference is the material, high-end boron nitride products need to use high crystal, high cleanliness, low oxygen content of raw materials, so that the product quality is excellent; On the other hand, the compression density is uniform, uniform heat, only with the above properties of boron nitride products to prolong its life, enhance the corrosion resistance, to adapt to a variety of working environment.

The boron nitride ceramic products produced by the company have reached the above high-end technical level, and the quality and performance of the products are comparable to similar foreign products.

Boron nitride composite ceramic material is a composite product of boron nitride and other ceramic materials (such as Si3N4, ZrO2, SiC, etc.), can withstand high temperature above 2000℃, its dielectric strength is more than 40kv/mm. The key technology of the material is uniform compression, uniform heating, reduce excess impurities, make its composite closer or more uniform reaction, extend its service life, ensure its use quality.

Because the material is high hardness, high temperature resistance, and other metal materials are not infiltrated, no pollution, at the same time has excellent mechanical strength, high thermal conductivity and shock resistance, in high-end equipment and special industries have been widely used. In addition to high temperature resistance and lubrication, the material is widely used in the fields of continuous casting separation ring, metal atomizing nozzle, rocket nozzle, amorphous strip and so on. The vacuum conductive ceramic evaporative boat can be made by combining its conductivity with titanium diboride.

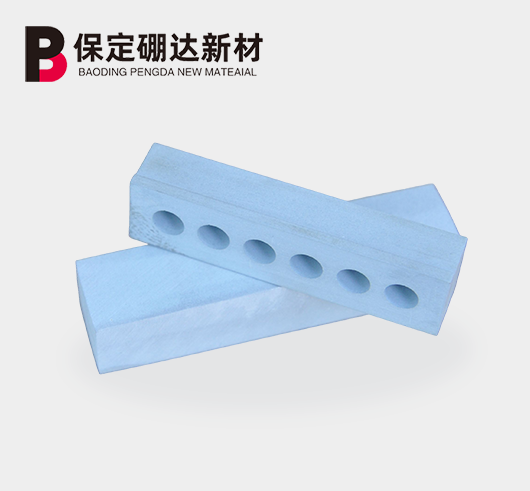

At present, boron carbide is the main basic material for neutron absorption and shielding materials commonly used in special equipment of nuclear industry. In order to improve neutron absorption ability, pure boron can be used to make shielding materials. After special production process, the formation of high purity boron dodecide, compared with similar boron carbide ceramic materials, under the same shielding and neutron absorption standards, has the advantages of lighter weight, smaller volume and so on.

In view of the urgent demand of nuclear engineering construction and nuclear power facilities for materials with good moderated absorption/shielding effect, light texture, small volume and radiation resistance, our company has cooperated with relevant scientific research institutions to develop new boron-aluminum based neutron protection composite materials. Through the repeated trials of our R&D staff, we have successfully prepared a variety of sizes and composition products. After testing, the material uniformity, crystallinity and density of the product have reached a high level, and the preparation process, mechanical properties and neutron slowing absorption properties have reached the relevant standards.

Boron carbide/aluminum composite ceramic products (nuclear shielding and neutron absorbing materials) - Boron carbide/aluminum composite ceramic materials are mainly used in nuclear industry spent fuel dry storage facilities and nuclear shielding facilities to ensure the critical safety and radiation shielding of spent fuel during storage and transportation. It is known that the boron carbide/aluminum neutron absorbing materials used in the nuclear industry generally have problems such as short service life and poor corrosion resistance.

Our company through technical research, improve the production process, so that the materials fully reaction synthesis, the formation of real ceramic materials, so as to solve the above application problems.