Time:2022-09-18 Source:

New aluminum-based neutron protection composite project

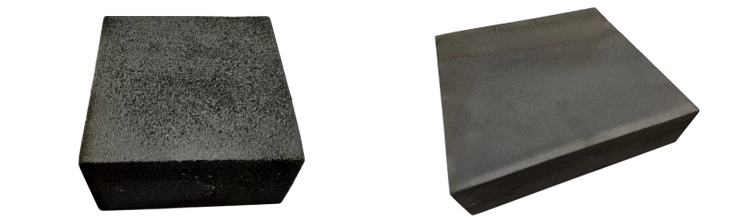

Reprocessing of spent fuel refers to the process of disposing of spent fuel elements discharged from a reactor, separating and recovering unburned uranium and newly generated plutonium, and disposing of radioactive waste at the same time. The recovered uranium and plutonium can be reprocessed into fuel elements and returned to the nuclear power plant (hot reactor or fast reactor) for use to improve the utilization rate of nuclear fuel. At the same time, reprocessing of spent fuel significantly reduces the toxicity and volume of radioactive waste requiring final geological disposal, and improves the safety of disposal. Therefore, reprocessing is of great significance to the sustainable development of nuclear energy. During spent fuel reprocessing, highly radioactive materials (mainly processes or equipment with high plutonium content) are usually disposed of in the glove box. Three different types of glove boxes are mainly considered for precipitation, filtration and drying and roasting according to different forms of materials. In view of the urgent demand for materials with good moderated absorption/shielding effect, light texture, small volume and radiation resistance in spent fuel reprocessing engineering, it is imperative to develop a new aluminum-based neutron protection composite material system.

In 2019, the project was initiated by the State Administration of Science, Technology and Industry for National Defense. Beijing Institute of Technology, China Institute of Radiological Protection and our company formed a project research group to jointly develop a new boron-al-based neutron protection composite material. At present, the test of the project has been completed, and the test samples have been preliminarily tested. The next step is to optimize the process of large-size samples to greatly improve the neutron shielding absorption effect of the composite materials and achieve the small-batch production capacity of large-size components.

The new boron-aluminum-containing neutron protection composite material is mainly used in the reprocessing process of spent fuel reprocessing, such as glove box, and forms independent intellectual property rights. It will greatly improve China's scientific research and production capacity and international competitiveness in the field of neutron protection materials, so as to effectively support the construction and development of domestic spent fuel reprocessing projects. It also lays a solid technical foundation for the subsequent promotion and application in other fields.